WGAN-TV | Matterport Pro3 Camera for Construction Progress; FM and IoT19524

Pages:

1

WGAN Forum WGAN ForumFounder & WGAN-TV Podcast Host Atlanta, Georgia |

DanSmigrod private msg quote post Address this user | |

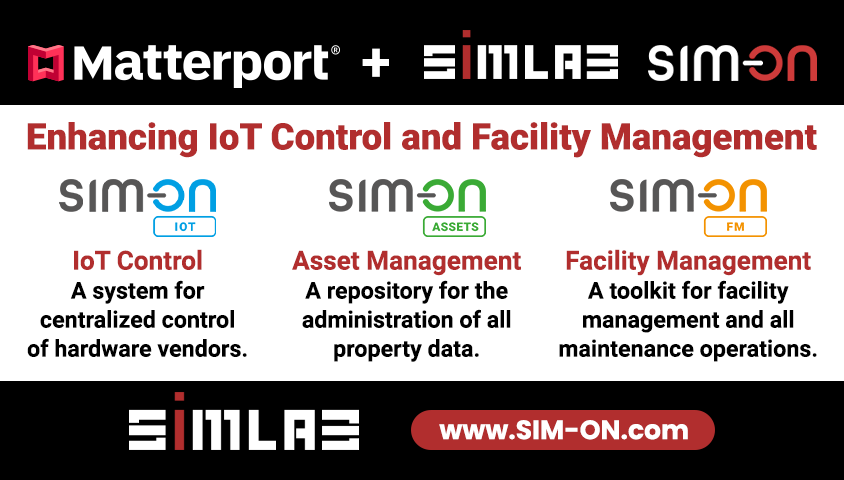

Video: 260-WGAN-TV on Location at Geo Week 2024 | Matterport Pro3 Camera for Construction Progress; Facilities Management and IoT | Guest: Matterport Staff Sales Engineer Kyle Ditto | 12 February 2024 | Episode #260 Image: Matterport Staff Sales Engineer Kyle Ditto | Image by WGAN-TV on Location Managing Editor and Host Dan Smigrod Geo Week 2024 in Denver (Colorado Convention Center) 11-13 February 2024 | Matterport Digital Twin courtesy of MatterFix.io Founder Mike Vorce (@MatterFix) WGAN-TV on Location at Geo Week 2024 in Denver, Colorado Matterport Pro3 Camera for Construction Progress, Facilities Management and IoT Episode Overview (Summarized by ChatGPT-4): In this episode of WGAN-TV on Location, we're joined by Kyle Ditto, an enterprise solutions engineer at Matterport, directly from Geo Week 2024 in Denver, Colorado. Kyle provides in-depth insights into Matterport's strategic direction within the AEC (Architecture, Engineering, and Construction) industry, their advancements in digital twin technology, and the impact of their latest Pro3 camera equipped with LiDAR technology. Key Points Discussed: 1. Introduction to Matterport at Geo Week: Matterport's significant presence [10' x 10' booth] at Geo Week 2024 highlights their commitment to penetrating deeper into the AEC industry, including sectors like oil, gas, and utilities. The focus is on the Matterport Pro3 Camera and the ability to generate BIM and CAD files from digital twins. 2. Integrations and Customer Workflows: Kyle emphasizes the seamless delivery of BIM and CAD outputs into the Autodesk Construction Cloud, enhancing integration with customers' existing workflows. 3. Accuracy and Efficiency: A common query from attendees revolves around the accuracy of Matterport's digital twins. While competitors may offer higher accuracy, Matterport prides itself on efficiency and accessibility, making high-quality digital data more available to a broader audience. Use Cases at Geo Week: 1. Facilities Management: Matterport transforms facility management with photorealistic renderings, improving asset location and maintenance processes. 2. IoT Integration: The integration of IoT sensor data with digital twins offers a revolutionary way to visualize and address equipment issues within a facility. 3. Design and Construction: Matterport aids in creating as-built documentation, monitoring construction progress, and ensuring projects stay on track and budget. The Matterport Advantage: The Pro3 camera's speed of capture and ease of use position Matterport uniquely in the market, catering to users requiring efficient, accurate, and accessible digital twin solutions without the need for specialized training or equipment. Platform Extensibility: Matterport's platform allows for custom modifications and integrations, making it a versatile tool for asset management, documentation, and collaborative efforts in facilities management, design and build projects, and IoT applications. Conclusion: Kyle Ditto's insights from Geo Week 2024 underline Matterport's innovative approach to digital twin technology. By balancing efficiency with accuracy, Matterport is making strides in democratizing 3D data for a variety of industries, simplifying workflows, and enhancing project management and facility operations. The episode sheds light on the future of digital twins and Matterport's role in shaping that future. WGAN-TV on Location Guest: Kyle Ditto, Enterprise Solutions Engineer, Matterport WGAN-TV on Location Managing Editor and Host: Dan Smigrod Join us next time on WGAN-TV for more insights into the evolving world of digital twin technology and its impact across industries. --- Transcript (below) - Hello, my name is Kyle Ditto. I am one of the enterprise solutions engineers here with Matterport today. We are at Geo Week in Denver. This conference is very important to us as we continue to dive deeper into the AEC industry, as well as oil and gas, utilities, et cetera. One reason that we're able to penetrate markets such as that is our newfound Pro3 camera, that's a LiDAR-equipped laser scanner, and another major platform feature that we're really pushing at this conference is our ability to produce BIM and CAD files from the digital twin. So we still have our bread and butter proprietary digital twin platform, but we're trying to meet customers where they are by producing the various assets they use in their existing workflows. - [Dan Smigrod] And Kyle, are you talking about integrations with Matterport at Geo Week? - It's not top of mind, although we do have pre-built integrations with Autodesk Construction Cloud, so for those BIM and CAD outputs, they can be seamlessly delivered into the Autodesk ecosystem and integrated into our customers' existing workflows. - [Dan Smigrod] And what are the kinds of questions that you're hearing from those attending Geo Week? - I would say probably the number one question we get relates to accuracy. So a lot of our competitors will say they can get one millimeter accuracy, which we don't claim to do, although our biggest benefit is in the ability to share and access this data in a way that wasn't previously accessible to laser scanning customers, so we get you 80 to 90% of the way there to the highly dimensionally accurate point cloud that a lot of these customers are looking for, but we beat our competitors on efficiency. So you can scan 100,000 square feet in probably about an hour's worth of time, where a lot of the other higher end laser scanners, that could be a multiple week job. So that's typically where we fit into the equation. I also ... the only other comment I'd make on accuracy is a lot of times, when folks come up to us asking if we can get to a millimeter accuracy, they don't necessarily have a good reason as to why. It's sort of this industry standard, but there isn't necessarily always a rational reason behind it, not to mention, some of our customers will tell us, if that is indeed your goal, you'll probably show up onsite with a laser [Leica DISTO] or a tape measure yourself. So we feel as if we can produce a very competitive output from an engineering perspective while at the same time producing a digital twin that's highly accessible to the masses without any specialized hardware or software. - [Dan Smigrod] And at a conference like Geo Week, can you speak to the use cases that are coming up where Matterport is a better solution than perhaps some of the other higher-end millimeter accuracy scanners that you're discussing? - Sure. Yeah, so we cover a wide variety of industry verticals, and within those verticals, I would say our top use cases are facilities management, so previously, a lot of folks in FM would rely on 2D imagery or dashboards to manage these spaces. We give them a photorealistic rendering of that environment so they can understand how it's laid out, where all their assets are located within that space, they no longer need to go hunting down information in their ERP or in their ERP system or in their asset management database, whatever they're using, they can use the photorealistic experience to walk through the space, locate that piece of equipment, understand what maintenance it may or may not need, and resolve that ticket faster than they could before. So facilities manage is probably one of our top use cases. Otherwise we're actually, we're now getting into the IoT space, so previously, if you had IoT sensors in your facility, the data streams would end up in a 2D dashboard, and all that, the only information that would be provided is an asset tag. So you can see asset number X-Y-Z-A-B-C is operating out of the standard operating threshold, as in there might be an error occurring, could use some maintenance potentially, you may have to diagnose the issue. What we're getting into in the IoT space is the ability to visualize those same data streams on the digital twin itself. So rather than saying, asset X-Y-Z-A-B-C, you can say, "okay, I see, I can walk to that, I can virtually walk to this piece of equipment. I can see it's in the northwest corner of this particular portion of the facility, understand the equipment I may need, I see it's eight feet above the ground so I'll bring my ladder, I'll bring the appropriate toolkit, and then I'll go resolve the issue." So we're seeing that gaining a lot of traction now as well. - [Dan Smigrod] Kyle, you've mentioned facilities management as a use case. You've mentioned anything that has to do with IoT, which could be a subset of facilities management. Is there a third use case that you're running into here at Geo Week? - Yeah, yeah, certainly. I would say, especially for Geo Week, design and construction is probably one of the most top of mind use cases for customers that are attending this conference, so we have a lot of customers that will take a scan prior to a renovation or a construction project use our, either use our services or create the as-built documentation with our point clouds, and then subsequently take periodic scans during the construction process to monitor progress as well as hold some of their subcontractors accountable, because in a lot of instances, a subcontractor will say, "Oh, we've already completed X," and either they may be lying or exaggerating, but with periodic scans, you know the exact state your project is currently in so you can keep your projects on time and on budget using that digital twin as the living, breathing documentation over the course of the project, and then of course when it's completed, one more round of scanning in order to update those as-builts and keep those documents handy for future engagements. - [Dan Smigrod] So is construction documentation, what I think of as weekly or monthly construction progress documentation, the subset of design build? - Yes, I would say so, mm-hm. - [Dan Smigrod] And of the three use cases that you described, the Matterport Pro3 Camera, the first thing you described was speed of capture. Is that the only reason or is that the best reason, versus perhaps the other scanners... I think I'll ask my question differently, because it sounds like in those three use cases, the Matterport Pro3 is good enough in terms of the accuracy. - Right. - [Dan Smigrod] And therefore, it doesn't matter that the other scanners here that might be $40,000, $80,000 or more can be more accurate. So is that the sweet spot for Matterport with the Pro3? Is anything that really doesn't require the level of accuracy but requires the speed of capture for those three verticals that you described? - Right, I would say that's accurate. We win on efficiency. Also, our platform is highly accessible and easy to use. We also consider our capture process to be walk-up easy, so you don't need any specialized training at all. Basically, you procure the camera, you connect it to an app on your phone, and then within 10 to 15 minutes, you're off to the races. So unlike the higher end laser scanners that require specialized skillsets in order to operate them, any average Joe can pick up and become an expert Matterport scanner, I would say in 15 minutes or less. So ease of use and then efficiency, I would say, is where we win on the hardware side, and then on the platform, it's similar, that's definitely the swimming lane that we want to be in, we want to be the digital twin for the masses. We want to democratize access to the 3D data that was previously only accessible to engineers with specialized hardware and software. So that's typically how we position Matterport. We're not trying to go head to head with any of the other vendors at this particular conference, because we see ourselves in a class of our own. - [Dan Smigrod] And just last question, could you expand more on the Matterport platform in the context of facilities management, design and build, and? - IoT was the last one. Yeah. - IoT, thank you. - Yeah, so our platform is highly extensible. We do have a SDK and API available to add custom components to a digital twin or retrofit the digital twin to fit within an existing workflow, so we have plenty of capabilities that will allow our customers to, it's not a one-size-fits-all. A lot of our implementations are quite bespoke in nature, but the platform just works. You sign up for an account, you scan a model, it shows up in there, and then you're ready to take accurate measurements, document the facility with operations and operating manuals or any other relevant documentation to manage your assets, and it can also be used for collaboration purposes. So with our notes feature, you can tag other users and call out certain things. So, "Hey Mr. Plumber, hey Mr. Electrician, "there's an issue here. "There's a crack in this pipe. "This light bulb is out." Those are really basic, simple examples, but rather than send an email or any other message and say, "Okay, go to this particular coordinate "in the space," and fix an issue, you can provide them, again, the link to the Matterport model so they know exactly where the issue is taking place, they understand the equipment that they would need to show up with in order to get it done. So I'd say from a platform perspective, it's the ability to measure with accuracy, document the facility using our MatterTag feature, as well as collaborate in real time with the background of the photorealistic digital twin as opposed to a standard messaging tool. - [Dan Smigrod] Kyle, thank you very much. - Of course, thank you. |

||

| Post 1 • IP flag post | ||

|

Fathom3D private msg quote post Address this user | |

| Great conversation, good to see how this is being presented. Thanks for sharing! | ||

| Post 2 • IP flag post | ||

Pages:

1This topic is archived. Start new topic?