Transcript: WGAN-TV: Matterport + NSPECT: Record Inspections and Compliance18763

Pages:

1

WGAN Forum WGAN ForumFounder & WGAN-TV Podcast Host Atlanta, Georgia |

DanSmigrod private msg quote post Address this user | |

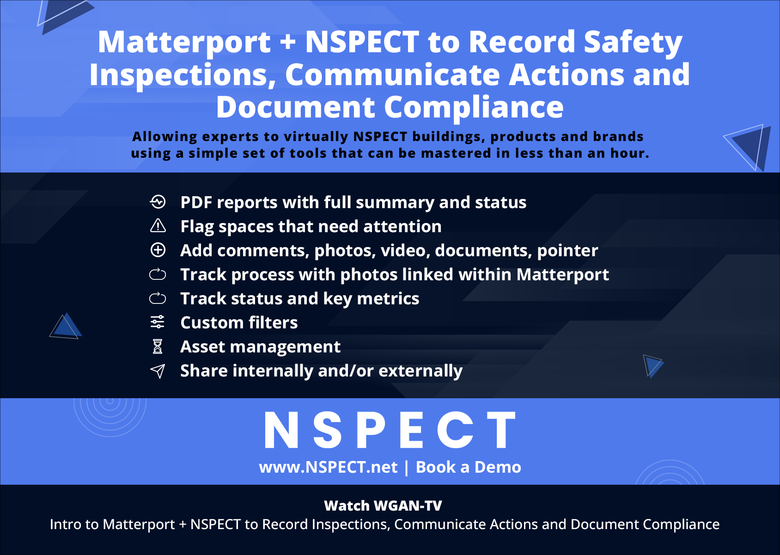

| NSPECT is a WGAN 3rd Party Service Provider ---  www.NSPECT.net WGAN-TV | Intro to Matterport + NSPECT to Record Inspections, Communicate Actions and Document Compliance | Guests: NSPECT Vice President of Marketing Stuart Gilly and NSPECT Founder Brandon Foreman | Episode #191 | Thursday, 8 June 2023 | www.NSPECT.net Video: Meet NSPECT | Video courtesy of NSPECT YouTube Channel | June 11, 2022 Transcript | WGAN-TV | Intro to Matterport + NSPECT to Record Inspections, Communicate Actions and Document Compliance Hi All, [Transcript below ...] If you use Matterport for Facilities Management, Safety Inspections, Compliance or Collaboration, then Matterport + NSPECT will help you: 1. record safety inspections 2. communicate actions 3. document compliance On WGAN-TV Live at 5 (5 pm ET) on Thursday, June 8, 2023, get a deep-dive demo and discussion: WGAN-TV | Intro to Matterport + NSPECT to Record Inspections, Communicate Actions and Document Compliance My guests are: 1. NSPECT Vice President of Marketing Stuart Gilly 2. NSPECT Founder Brandon Foreman NSPECT allows experts to virtually NSPECT buildings, products and brands using a simple set of tools that can be mastered in less than an hour, including: 1. PDF reports with full summary and status 2. Flag spaces that need attention 3. Add comments, photos, video, documents, pointer 4. Track process with photos linked within the Matterport tour 5. Track status and key metrics 6. Custom filters 7. Asset management 8. Share internally and/or externally Book a one-on-one demo at: www.NSPECT.net Questions that I should ask Stuart and Brandon on WGAN-TV Live at 5? Best, Dan NSPECT Links 1. NSPECT Website 2. NSPECT Vice President of Marketing Stuart Gilly 3. NSPECT Founder Brandon Foreman 4. NSPECT YouTube Channel Transcript (below) |

||

| Post 1 • IP flag post | ||

WGAN Forum WGAN ForumFounder & WGAN-TV Podcast Host Atlanta, Georgia |

DanSmigrod private msg quote post Address this user | |

| WGAN-TV | Intro to Matterport + NSPECT to Record Inspections, Communicate Actions and Document Compliance | Guests: NSPECT Vice President of Marketing Stuart Gilly and NSPECT Founder Brandon Foreman | Episode #191 | Thursday, 8 June 2023 | www.NSPECT.net Transcript (Video above) [00:00:02] Dan Smigrod: Hi all, I'm Dan Smigrod, Founder of the [www.WeGetAroundNetworkForum.com]. Today is Thursday, June 8, 2023 and you're watching WGAN-TV Live at 5. We have an awesome show for you today: Intro to Matterport + NSPECT to Record Inspections, Communicate Actions and Document Compliance. Here are subject matter experts: Brandon Foreman, Founder of [www.NSPECT.net] and Stuart Gilly, Vice President of Marketing of NSPECT. Stuart, Brandon, good to see you today. Thanks for being on the show. [00:00:40] Stuart Gilly: Thanks Dan for having us. [00:00:44] Brandon Foreman: Absolutely, Dan. Good to see you again. [00:00:45] Dan Smigrod: Awesome. Stuart, we're going to do some role-plays in a few moments, facilities manager, real estate agent, a compliance person, [national hotel/restaurant brand], but before we jump into those role-plays, how about giving us the big picture about NSPECT? [00:01:12] Stuart Gilly: NSPECT was really created as us being Matterport users. What we were finding was we had these great digital twins that really gave us a lot of visibility into a project. Where we found things falling apart was; here we are in a boardroom with a bunch of people and now we have data like we've never had before. We have action like, "hey, we need to go get this thing done' or "this has to be fixed," or this is an opportunity and yet, here we are all jumping in our emails and taking screenshots of the screen and trying to text and send all these different ways to communicate what needs to be done and it hit us. It's like, well wait a second, this isn't actionable, how do we take this really awesome technology and how do we get it into the hands of the people who aren't in the boardroom where they can actually go out and in asynchronous way, be able to go out and achieve the goals of what the action items are, so NSPECT was born. We really set out to try to figure out how to make Matterport models actionable and we're excited about NSPECT because that's what it's doing. We're watching it solve problems for our clients, we're watching it save them time and money and being able to take an awesome tool like Matterport and be able to help them deliver better business results. In the simplest form, that's what we do. We're taking this digital technology and putting it out into the hands of the people in the field who can make the difference. [00:02:50] Dan Smigrod: The sweet spots for NSPECT, perhaps in terms of verticals? [00:02:55] Stuart Gilly: Yes. We'll talk about some of these today, but hospitality, facility management, inspections, obviously, facility management, we're going to talk a little about real estate, home inspectors, we're just seeing it in AEC. We're seeing it in all these different verticals where you have things that are happening out in the field and there's real-time decisions that need to be made at the boardroom level, or at an upper management level, and they need to be pushed back down in the field so that people have instructions for workers that are accurate and timely. We're trying to save all these different verticals on travel time. We're trying to help make decisions quicker and faster and we find that through the asynchronous communication of it, we're just seeing better business results happening from those. [00:03:43] Dan Smigrod: You mentioned three benefits: faster, easier, saving; I think, saving time, saving money, saving travel, are there other benefits when you take Matterport and add NSPECT? [00:04:01] Stuart Gilly: Yeah, absolutely. Well, I think one of the other things is that you're also creating vision into a property or a project that traditionally has just taken longer to show up. You're also eliminating the need for a bunch of 2D digital pictures that are sent through via email. Obviously now we're getting into what is 3D digital technology and how does it make businesses run better, but I think with NSPECT partnering with Matterport, it's a holistic tool in which somebody can walk through a building or a property quickly and start tagging those actionable items that need to happen and know that they can quickly deliver that out to multiple parties and be able to not slow down the process of what needs to happen. And obviously we'll jump into that a little bit later and show you exactly how that happens and you can see how quick those reports can be sent out. [00:05:00] Dan Smigrod: Brandon, can you speak to those reports? [00:05:04] Brandon Foreman: Yeah, somewhere along the way, as Stuart said, we were customers first and we ended up becoming what we like to call ourselves, the reporting engine for Matterport. We'd like to think we sought out to do that originally when all we were trying to do is to make models actionable for people to be able to take a 30,000 square foot facility and go markup -- "here's 60 things that need to be done." Let's say maybe it's paint on the wall or there's a cracked tile or anything. It's something you need somebody to do. The guy who needs to do the work doesn't need that 3D model, he just needs to know where I need to go to do the work. When you can walk through this property, when you can NSPECT it, and then you can text a link to someone on the team and say, "here it is" and they immediately get, when was the model taken? Where was it actually added? Let me see where it is inside the space, point exactly to where the problem is, tell me what needs to be done, give me the status, give me the urgency. If we push that, whether it be to a secure link or if we push it into a PDF, or if we push it into a work order management system with APIs, it gets it right into the hands of the guy who actually swings the hammer, for lack of better words, and lets him get to work right away. Then when he's done, he can snap a picture, upload it back in and the guys back in the boardroom or the conference room, they know it's been done. It gets it actionable, it gets it fast and somehow along the way we ended up being that reporting engine. [00:06:37] Dan Smigrod: You mentioned reports and you mentioned PDF and I think I heard photos, so essentially taking photos within a Matterport tour. At a tactical level, what are the things that you're providing that person in the field with, within that report, within that PDF.? Again, you mentioned photos, are there other things that you're annotating this space to communicate action items? [00:07:05] Brandon Foreman: Absolutely, so we allow you -- we give you the ability to annotate on top of a 3D model. What we're doing, when you get down, there's a lot of technology, there's a lot of IP that sits behind it. But at the end of the day, we're taking something very complicated, a 3D digital twin and bringing it back in reverse. It's being a software company and we'd like to think in the high-tech space. We actually take a step backwards. A lot of people are not wanting paper, they're wanting software, they're wanting websites. But when we can go into that 3D model, annotate on top of it, give instruction, allow commenting on that, and then push that back out where we extract a 2D image out of the 3D model, drop that down into a PDF or into just a web link that's going to give them all those annotations, all of the texts, context, all of the information that they need to be able to make decisions. It's not what we think is actionable. The customers are defining their inspection type, so what are their statuses for things? What do they categorize information as? What do they consider urgent? Or what are the flags that they need to have? It's built on the premise that you can jump into the software within less than an hour. That's one of our mantras on the dev team is, no matter what we do, you've got to be able to implement this and be off to the races in less than an hour. You get all of that information, whether you want it online with a link, if you want it on your mobile device, if you want a PDF and email it out to somebody. [00:08:41] Dan Smigrod: It's two pieces, I'm hearing. The first is on the Matterport tours, the annotation. I think of Matterport as having the ability to tag, and within those tags, there's opportunities to add comments or photos, videos, documents, pointers, or all those things that let's say a Safety Inspector wants to call attention to; issues on a construction site, and those 100 issues need to be worked through. Then the person on the field who's actually responsible for the punch list of taking care of those safety issues, does that mean they can filter and say, "I want to deal with fire extinguishers first. I want to deal with some lighting issues. I want to deal with the soda cans that are sitting on the edge of the 2 by 4s before the drywall goes up, and we need to make sure those get removed." Is that by the person in the field? Can they sort by the issues that have been identified? [00:09:47] Brandon Foreman: Correct. It's one of the examples we'll share with you later today. We've got a sample construction site that's pretty much wrapped up. It's a house and everything looks great, but there's a couple of problems throughout it. We call them endpoints, which is very similar to a Mattertag, but allows you to put a little bit more information to it. Allows you to collaborate real time with your team inside of it. Allows you to issue whether that endpoint is resolved or if it's still an open pending issue. Just as you said, we can say, "show me just everything that deals with paint." "Show me everything that just deals with electrical." "Show me just the plumbing." We can filter this out, and not only can we do that, but if you think of this in a practical application to where say we've got a home or even a business or one of our large hotel partners, we don't need to send someone there to actually scan the facility. They can get the model scanned. We can have someone back at corporate. They can go through and mark everything up. Then we can say, "we need to send this to the electrician." Well, the electrician gets a link, and it's going to sound very simple, Dan, but it's the simple things that make life easy. I think we've all lived the pain of where we're trying to get our vendors and people to collaborate inside a software and we just want simple information. I talked with the client the other day and not to go into a long story, but if we'd run that example, say we've got a property or it's a house. I'd mark up the problems that I've got, and I send this to my electrician or I send it to a painter, doesn't matter who it is. I just send them the link and I say, "I need to know what it is going to take in order to get this fixed? Tell me, how much money and how much time?" Well, when he gets a link and he clicks that while he's sitting at a restaurant or he's sitting there at lunch, he opens it up on his phone and he sees the picture. He sees the urgency, he sees the detail. He sees the narrative that he's been told by the person that sent it to him. Then he's got a button right there that says, add comments. He clicks, he types his name, he types back. "It'll be two weeks and $200," and then it moves to the next one, "three weeks, $500." Meanwhile, we're getting that information and we're adding that back into the conversation right inside of NSPECT. We didn't have to create an account for him. We didn't have to name him as a user. We didn't have to buy another license. We didn't have to get him signed in. We didn't have to make sure his browser was taken care of. We didn't have to deal with all of that complexity. We're able to get the information immediately. We all know when you walk around on these sites with a lot of these guys or when you're working with whether it be construction or brand compliance, people will point to the thing. That needs to change. Well, what is it going to take? You can rattle that information fast. But how do you get that institutional knowledge back into a system where somebody can go, "I" need to capture that, but I need to do it for something on the other side of the country, and I need to do it fast," and that's what we do for him. [00:12:45] Dan Smigrod: I could imagine part of what I'm hearing is that the person that may be identifying the issues, and let's say they come up with 200, 300 issues can easily be filtered by the trades that need to work on that particular challenge. This is the paint person or the drywall person or the finishing person or the floor person. They don't need to see all 300 items that have been tagged. They just need to see the ones that are relevant to them. If I hear you correctly, Matterport + NSPECT: it enables exactly that. [00:13:19] Brandon Foreman: Correct. Here's the other thing. I say this, we love Matterport, we love our Matterport models. But when you get into some of these really large projects, when you're in 50,000, 75,000 square feet, even 20,000 square feet, you still have to move around the entire place. That takes time for someone to find -- "where are those problems?" "What do I need to identify?" "Where is the mechanical closet?" If it's an electrician, we've got a breaker that's out. If you've never been into a building -- "I don't know where that is," I got to go -- Now, we're wandering around inside the model looking for a mechanical room. Then we got to get into the mechanical room and then we got to go find where it was. Whereas NSPECT, you can say, "show me all the electrical issues," and when you can click one button, it says, "go to point." We're going to take you directly to that Npoint. We're going to show you exactly where it is and we're not just going to take you as a snap into it, but we're going to take you into a fly-in just as Matterport does. You can get some idea, "oh, I'm in the front lobby. Now let me see. I've flown around the back corner. I went down the hall, I went to the right and now this is where it is. I've got an idea of where I'm going." [00:14:28] Dan Smigrod: Well, I think that is a deep-link. Is that what we're talking about within Matterport? A specific place to fly-in to the Matterport tour where that problem or challenge or opportunity is. [00:14:41] Brandon Foreman: Correct. We use some of the deep-link on when you're inside the application. We deep link also from the PDF reports and other things there. But at the same time, if you already know what you're looking at, if you've been working on a job site, you may not need the deep-link. You just might say, "just give me the report and let me see that. This is a breaker can, and I can see the breaker in the top right lug 22 is broken or it's not working. I know exactly where that is. I clicked my 'add to comment.' I'll have it fixed before the end of the day. I go out and get to work, and I didn't have to start -- I didn't have to get into a whole other application, and I didn't have to change every way of work," we end up getting whether it'd be the brand or the construction or the management. Our clients are getting more of their vendors and more of their team members, even their internal team members where it's like, "hey, we inspected this property for brand compliance." We're not talking about construction. They just send it over to somebody and they mark everything that's wrong. Then somebody can say, well, "here's what they need to do, the corrective action. This is what's wrong, or actually no, we'll allow that." We got someone else to use the software without having to get them into the software. [00:15:53] Dan Smigrod: Yes. Stuart, I see you nodding. Did you have other things to add what Brandon said? [00:15:59] Stuart Gilly: Well, I think it's not always about what's wrong either too. We've even seen a hotel client who has talked about, "we like the idea of even being able to use these to train people." It's not always about what's wrong. In the brand standard, it's like they're able to go in and drop notes and comments so that somebody can actually use this as a training tool as well, even from a safety standpoint. "This is where you want to be." You can fly through location, you can see these things. We don't always want to think of NSPECT as being the thing that's pointing out everything that's wrong as much as sometimes it's pointing out what is right, and it's a way that we can also train and we can pass on the knowledge to others inside of an organization or even vendors who've never been inside of a facility. This is what's right. This is how we want it built. This is the way we can look at it. Anyway, it's always nice when your clients are bringing it back to you in other ways that they're using to make it useful and it's just, "okay, that's great." It's not always about the problem in the field as much as it is sometimes like, "what is the brand standard?" "What do we need to hold ourselves to?" [00:17:12] Dan Smigrod: Brandon, if I could go back to you on facilities management, you mentioned work order management software. Are there any specific ones that you've presently built out to or plan to build out to? [00:17:23] Brandon Foreman: We don't have anything specific that we build into. We've built the Npoints to where people can grab data. We can push data to Npoints that are out there. We integrate with a number of third-party tools, but that's the cat and mouse game in the development world. If I build out these 27 different work order management systems, everybody's going to need the 28th and 29th that we haven't gotten to yet. We felt it was best at this point to build the infrastructure and the Npoints push-pull to where clients can grab data that they want themselves or tell us where do you want us to push it to or go back old school and will give you a CSV file and let you take it where you want. [00:18:06] Dan Smigrod: Okay. Is there a challenge with -- I'm thinking about what large companies tend to have -- there's an expert in the company somewhere. Company may have hundreds or thousands of employees and those people I imagined get pressed into problem- solving that may involve getting on a plane to go see the problem in person. Is there an aspect of Matterport + NSPECT that enables the experts not to have to travel so that their time is better used. Maybe that's a Stuart question, I see you nodding there Stuart. [00:18:52] Stuart Gilly: That's been some of the great feedback that we've gotten is that there's a lot of institutional knowledge with a lot of the retiring workforce. Right now, we're finding people are leveraging NSPECT for exactly that. They may have a subject matter expert or multiple on their team, but they don't have enough. There's more demand, there is supply and so yes, we're absolutely seeing that right now. We have a client who they have a one-person that is really good at this and right now they're leveraging it from a standpoint of, "okay, how do we get NSPECT in front of him so that he's not having to jump on planes and fly around." He also likes to wake up his kids sometimes and drive them to school. It's this idea that not only can we also multiply their own knowledge, their intellectual capital, by being able to have those people make a bigger impact without having to jump on planes. Obviously that saves time and it saves money and it's allowing these organizations to be able to make faster, better decisions. But at the same time, think about the training of that too. Now we have ways that institutional knowledge can be passed on to the next generation. We're really excited about that. That's a struggle and a lot of different industries right now, Dan, and I know you dig in on this stuff, so you know that. We know in the utility space there's a huge gap between the people who know how to do all this stuff and the next-generation that a lot of them haven't learned because they've been relying on technology more than manual processes in an old school SOPs which have been an issue. [00:20:36] Brandon Foreman: I'll jump in there. Stuart won't say names, but Dan, what we've found, this will go to what Stuart was talking about before. I kind of lean on the negative sometimes, always finding problems. But on the plus side, we've got a number of clients that have started using -- Stuart probably knows who I'm talking about when we get here but -- if you think of a mechanical room, I'll give the example. You've got a mechanical room that's not just small, not just like the elevator and the HVAC system, but a decent size facility and you've got somebody on staff. You got one or two guys who are keeping this place going. Those guys get that information out, there's nothing necessarily that went wrong. A maintenance item is not wrong, we have to do maintenance on facilities. It might be that something went wrong inside during the day and then there might be just some things that were just regular maintenance. To try to describe, well, I went into the mechanical room and there was a piece of pipe and it was 18 inches to the right, this gauge and it was 5 feet off the ground and this is where the 90 degree elbow was that I had to -- you're spending so much time trying to explain that basically all you did was replace a fitting or you had to go into a fuse box and replace this particular fuse and then reset this breaker where because it's such a hindrance to pull that information out of those guys that just know how to fix it, where they're able to use -- We've got a number of clients now that are having these guys go in at the last hour of their shift, the last 30 minutes and say go into the model, I want anything that you touched or you did, go point on it, click on it, and then write out and tell us what you did today. We don't need to describe where to find it or how it was, here's the breaker, this breaker tripped. I had to go change this piece. This is what was wrong with it. A lot of them are even dictating and not even typing the information and then the clients are pulling that information out, basically and now we've got a log or a journal for all of the information that's happening in that room. When the next guy comes in, he's like, "I don't know what to do," but he can go through and be like, "what happens at this panel?" And he can read through: this happened and that happened and here's a year's worth of information because we knew Joe was going to be retiring so we started having Joe spend the last hour of his day doing this each day. [00:23:04] Dan Smigrod: I want to go back for a moment to the experts wherever they are across the country who have typically been flying in as the SWAT Team to come in and solve problems. Does Matterport + NSPECT flip the model so that the expert gets to stay at their own location and the space comes to them virtually? Help me out? I see some nodding going on. [00:23:35] Brandon Foreman: Here's the example I give everyone and hopefully drives it home. We've all probably had the unfortunate event where we either ourselves or family members had to go into the hospital and get an x-ray. Most of the time that x-ray is being read by somebody on the other side of the country now and it could be a radiologist that is sitting on his couch that gets an alert that rolls over and grabs an iPad and starts to pinch and zoom and look at it and go, "yes, we've got a fracture here," writes of his report and pushes it back and the ER, does what they need to do or they send you to the referral. We're doing the exact same thing at NSPECT. We're taking these guys who have the knowledge whether it'd be OSHA safety specialists that have retired, whether it'd be just general people that know the oil and gas industry and instead of them being able to do two to three site visits a week, we're moving them to where they're doing two to three visits a day, sitting at home and saving. -- Now I'll be the first one to say, we're not going to be able to NSPECT everything 100% of the time, but we can take a good 80% cut and say, "we're going to knock out these 20 facilities on Monday to Wednesday and then we're going to go see these two that made some big red flags for us on Thursday and Friday." [00:24:49] Dan Smigrod: Better use of the time of an expert? [00:24:52] Stuart Gilly: Absolutely. [00:24:53] Brandon Foreman: Absolutely. [00:24:54] Dan Smigrod: Let me just stay with this and I want to rattle off what I think I heard; is by leveraging the expert where they are, rather than having them come on site. That has enabled their productivity, perhaps to shoot through the roof because they're not spending time traveling. Second is, it may even be employee retention because as Stuart said, they get to wake-up in the morning, wake up their child in person, not by phone. Perhaps employee retention, it's saving time, it's saving money, it's moving the expertise back to the expert rather than the expert constantly having to travel or experts travel the country. Are there other benefits when you flip the model and have the model come to the expert? [00:25:56] Brandon Foreman: Take this one Stuart because I say it the wrong way. You say it much more eloquently than I do. [00:26:00] Stuart Gilly: I just want to use some of my own experience. I used to own a construction company, Dan, years ago and we had projects all over the US and there were days where I would spend all day trying to troubleshoot, as Brandon said earlier, and in my mind build what was being told to me over the phone. That was not a good use of my time. I'm not even sure I gave valuable information back because we were doing the police sketch. I'm like, is this what we're talking about? I'd find myself in those days I could spend time on four or five problems that day solving things from Atlanta to Houston and I didn't really get anything done because I didn't have a way to be able to physically see that. What's also being involved with that is I'm having to call other people. Now next thing you know, I'm pulling in four or five people to try to solve a problem that no one has real vision on except for the person in the field who's not describing it well. Yes, it's about keeping that subject matter expert at home or at home-based where they can be effective. But think about how many people are typically brought into a problem when we don't have all the information or we don't have enough information to make a quick decision and we're just seeing at NSPECT that these are the things that are being eliminated, that a lot of times people aren't even taking into account that that's a cost. That's a real expense to the business and it slows things down. We're moving into a time and space where you're slowing down your employees, you're keeping them from executing. You're starting to have cultural issues. You're starting to have people get frustrated with the systems and the processes. As Brandon says, I think we are a very simple tool, but I think through the simplicity of it, it has great impact and it keeps less people from having to deal with problems and it's allowing asynchronous communication to happen where it's delivering those results. It's not just about saving the subject matter experts' time, it's about saving the rest of the team's time. [00:28:04] Brandon Foreman: I'd add to that, Stuart, maybe you can jump in and say this better. I always say it the wrong way, to want to dance one of the benefits is when you send some of these subject matter experts out on a regular basis and they go see the same facilities in the same places and they're making the rounds. I've got to go see this every quarter, I've got to go do this. Relationships get formed there and friendships get formed there, and we want that with people. We want people to get along, but also it questions, Stuart, what's the term you used the other day? It's the integrity of that report. [00:28:44] Stuart Gilly: It's the integrity of the report. Is it one of those things where I'm like, "Dan, we're buddies. Can you just get this fixed so I don't have to mark this thing up, please?" "Yeah, I'll get it taken care of tomorrow." [00:28:54] Dan Smigrod: "Yes, please. I don't need that to end up in a report. Is that okay with you? Can you just go fix that?" [00:29:00] Stuart Gilly: Yes. [00:29:01] Brandon Foreman: When you take exactly what you guys are saying, if we take in -- with Matterport and with an iPhone and a Matterport Axis smartphone rotator, and we can tell that local manager, "Hey, I need you to once a month hit these scans." The scans are immediately going in and they get processed inside of Matterport. They get dropped into NSPECT. And now it's behind a curtain, it's Oz. They're looking out for the company and saying these are the things that need to be done. Here's some great work. As Stuart mentioned, we can point out these are really good things. We need to have our other franchisees look at this or this is unbiased. I don't have a relationship. I need to make sure that this is done right. [00:29:43] Dan Smigrod: If I'm hearing you correctly, that by having the inspection done remotely where there perhaps isn't a one-on-one personal relationship between the inspector and the on-site person that something that actually needs to get annotated, noted, documented might actually now happen. It may not have happened because of personal relationships that have been developed over time. I can see nodding yes, I'll just accept that. We've been talking a little bit somewhat of a high level without necessarily getting our hands around, "tactically, what are the deliverables?" Brandon, can you show and tell us? We understand Matterport. But now, where is the NSPECT? Exactly what is it that you're doing? Is there a report that you can show us? Is there a back-end demo or front-end demo that you want to show us? [00:30:43] Brandon Foreman: Yeah. We can jump in and I can share a screen right here and give you an idea of what we're looking at. We won't go into the ways, but we'll jump straight to the good stuff. We've talked about this report. At the end of the day I'm going to jump in. Let me share a screen. I'll show you real briefly how fast that gets generated and what's done, and then we can stop sharing and we can talk and then you tell me what you want to see. [00:31:04] Dan Smigrod: Sounds great. [00:31:06] Brandon Foreman: If I jump in here this is NSPECT in all of its glory of what we're doing here. We've got a number of Npoints that we placed here, but let's go to the meat of it. That quick we generate a report to where we extracted this 2D image out. This was reported by the WGAN Network. It was reported today. The category, this is a franchisee responsibility. It has not been resolved. It hasn't been approved. It's got a deficiency status. We don't have any additional comments that have been added at this Npoint. But we can see that this is no longer a valid offer. That this needs to be removed. This right here allows us to move through and see. You don't have to walk this entire facility. You're able to go directly to where all the Npoints are, you know who reported it, you know when the problem is, and if you need to basically add a comment and give feedback, you can give it right here. This is the same thing. If I go take this, if I scroll back up and say, let me generate a link and let's go incognito for a second. Then if you notice, we've got a tokenized link up there. Just as I was talking, you don't have to be logged into the application. You are able to come in with that secure link and I can still add comments back and say, "my name is Stuart. We are still doing this promotion. That's why this is here." That's going to get pushed right back to those inspectors. Just as we're sitting here, I can generate and say, let's take this all the way out to a PDF report level. I go and open the PDF and we are sitting here with a PDF branded with your company information pushed down. These reports are customizable, same thing. All the data that sits here. We've got all the information. I can email this right over to somebody and they can get to work right away on top of this. [00:32:53] Dan Smigrod: I think I'm seeing two things here. One is a PDF where somebody might just have it in the field, be making notes. But the other was the link to the report. When you send the link, that's the one where the communication can be two ways. [00:33:12] Brandon Foreman: Correct. We're not interactive obviously on a PDF. That's more printed out. It's the clipboard that makes the magic happen. Nothing gets done on a job site without a clipboard, print it out, put it on there and go. But then when the guy sits, the newer guy, the new clipboard is the iPad. He opens up his iPad and he's scrolling through with this link that might have just been texted to him. Then he's able to open up and then be able to say that this is done. He can give feedback. Then it starts coming back and forth from corporate, for lack of better words. [00:33:47] Dan Smigrod: Great. Can you go back to the screen just before the report was generated? [00:33:52] Brandon Foreman: Here, the inspection? [00:33:55] Dan Smigrod: Yes. If you could just show us a little bit of the annotation at this point of what it is, you can maybe move to a particular location within the Matterport space and then annotate that space. [I know we have a lot of technology going on here and it can cause a challenge between how we do WGAN-TV Live at 5 and the Matterport tour that you're trying to call up so there we go.] [00:34:24] Brandon Foreman: [That and Zoom everything slows everything down.] [00:34:28] Dan Smigrod: [That has nothing to do with NSPECT or Matterport. It's WGAN-TV and how we do what we're doing that's causing that latency. Otherwise it'd be snappy.] [00:34:42] Brandon Foreman: To jump in, if we look right here, we're at the front of this facility and this is your typical Matterport model. Everybody's used to this, which you wanted to do, we're used to that. But if I come down here, this is where I can start looking at it and go, I want to look at things that are franchisee-responsibility or I just want to look at what's a good idea for the franchise. I say, well what is this? Love the counter. I've got some information here. If I want, I can come in here and add some comments on it. I could manage the resolution status, put a link, some more pictures, and put anything we want here. But if I need more content, what is this? Well, I just couldn't go to Npoint and it's going to take me straight as you mentioned, Dan, kind of like a deep-link that we're saying that we actually love the counter that's sitting right here. This is what we want. If we said, well, we've reviewed that, let's get it in and just look at everything and go. Wait a minute, this is not an approved machine. Well, what machine is not approved in this facility? Let's jump over. Get right back, and we know this is the machine that needs to be moved and so that same machine, we've got it there and this is great where we've got all of this Matterport model, but we also just touch it for everybody so that we're there, I can flip over. I've also got annotations that are running. This is just 2D images. This is just uploading pictures from your iPad or your iPhone that you're able to go in and we do the same annotation here, and then they all get brought into that same report. The Matterport models are amazing. We can do that, but sometimes we just need to get information quickly. [00:36:20] Dan Smigrod: If you could just take me back to Matterport for a moment. If you could just maybe add one Npoint and go slowly over that addition, I think that would be great. [00:36:35] Brandon Foreman: Let's get us here. If I move my mouse around, which you can't see because you can't see my fingers. If I just stop moving my mouse, we get this red pointer that pops up. We're automatically selected so we don't have to go and click a whole lot of things to make it happen. I can click and then now I'm over here doing categories and information there. [00:37:01] Dan Smigrod: Just go slowly, if you would. To the top right where it says Npoint category and there were three not in the model, in the Add Npoint in the top-right. [00:37:14] Brandon Foreman: I'm going to show you just so I'll say so you're adding your point by stopping your mouse or you can just go in here and say add a point and then we can move it directly wherever we want. We'll put one here. [00:37:28] Dan Smigrod: Slowly. There were three items that came up, but for clarification, this is set by the company: what Npoint categories matter to them? This is not what gets shipped. [00:37:41] Brandon Foreman: Correct. These are what we call inspection types and so this right here is a franchise location, 100% everything that you see in this right panel, whether it'd be additional fields or anything, is defined by the end-user. They make as many different inspection types as they want and they're going to pick. [00:37:58] Dan Smigrod: In this case, there just happen to be three Npoint categories under Npoint status. The next item that would be typical, would show up in any companies or they could add or delete or change their Npoints status items. [00:38:17] Brandon Foreman: Correct. We can say this is a franchisee responsibility, it's something new and we can say there is a crack on the floor. [00:38:28] Dan Smigrod: Great. Then I understood that description. Then I see some boxes that talk about safety, brand violation, urgency, dispute. Once again, for clarification, those are all set by the client of what matters to them to be annotated to make life easy for them to simply check boxes to create the report. [00:38:53] Brandon Foreman: Correct and so as we make this, we've answered our questions, we've filled out our data that we want and we just say save. [00:39:01] Dan Smigrod: Again, for clarification, is there some point where I'm adding video or audio or photos in this process as well? [00:39:09] Brandon Foreman: Yeah, you can go in when you get down once you start editing your Npoints. Then that's where you can start coming over here. You can upload pictures, browse for files, different information, whatever it is that you'd like to place. [00:39:21] Dan Smigrod: Awesome, so any digital asset can be added to the annotation? [00:39:27] Brandon Foreman: Correct. [00:39:29] Dan Smigrod: At that point then you're generating a report unless you are going to show us something else, I take it off of the screen share? [00:39:35] Brandon Foreman: The last thing I want to show you is we just made this in front of everybody. That's how fast we bring this all the way down, we've got it here. It's not a rendering. We don't have to do anything special. We're ready to go and ready to start adding comments, real-time. [00:39:50] Dan Smigrod: That's awesome. I think we were going to try some role-plays. I'm not sure that it's necessary, but let's see how that goes. Stuart, which one do you want to start with? [00:40:03] Stuart Gilly: We can just talk about large national hotel/restaurant companies. If you take for example, let's say you have 100 locations around the country. Once a month, once a quarter, you're out capturing 3D images -- Matterport -- and you're creating these spaces and so you start thinking about, "well, how are we using these things?" That's a lot of data. How are we getting our teams? Who's using them? How are they leveraging those things? I think when we think about that, there's a lot of pain points specifically about inspecting their brand: brand management. How do we make sure that we're living up to those standards? We also see a lot with the PIPs: the Property Improvement Plans. What are the things that need to be done from a construction or a repair standpoint to make sure that those standards are being kept up? We also have seen where these hotels are also having new construction. they are taking over an existing property and so the instructions are just going to be punchless. There's always compliance. Then we talked about it earlier, just that whole unbiased inspection and review of the site. How do we make sure that we don't have Joe who always works all the properties in Arizona? Joe and all the managers have gotten to be buddies and now all of a sudden it's like we're not getting the real reports back because everything's always like "Joe, I'm going to take care of that tomorrow." Those are some of the issues that have been presented to us as pain points around their properties and what they can do specifically with Matterport. [00:41:53] Dan Smigrod: We can skip the role-play, but let's talk about the other categories and what the pain points are. You had mentioned residential real estate agents. What are the pain points for a real estate agent and how does Matterport + NSPECT help? [00:42:11] Stuart Gilly: Sure. Well, I don't want to talk about maybe the whole process there. Let's talk about home inspection. Let's talk about real estate agents. Let's talk about the buyer; because it takes all of them to create a sale or to close on a property. When you think about it, if someone is relocating from Phoenix to Atlanta. Well, they may fly in to see this property. But what happens when the inspection report comes back and all those things need to happen before closing, it's very expensive for relocation for somebody to be able to fly across the country. Now just take someone who's buying the house down the street. People are busy. They don't always have an opportunity to go by the house multiple times, check on inspections, what's been done, what's happening. What we're seeing is with leveraging Matterport and NSPECT and being able to have multiple parties be able to collaborate on that space, we can see inspections coming through from the inspector as far as what needs to be fixed, what needs to be repaired. The negotiation can be happening through the document. "Hey, we're good with that if you'll fix this." We start to see that -- can these deals happen faster? Can it be less painful? Can it be less travel? Less time for people to be able to do, and to be able to negotiate their way through closing opportunities? When you think about the real estate market, the same is true for the commercial market. Anytime you're talking about real estate and inspections and closings and things like that, that need to happen. We just believed that or we're seeing that NSPECT is a perfect tool to sit in-between all these different parties who like Brandon said, not everybody has to be an NSPECT user. Not everybody has to have Matterport. [00:43:59] Brandon Foreman: Yeah, I'd add that one of the big things I think about is real estate, commercial, residential, even property management. It's playing the game of telephone. If you're that Realtor, you've got somebody on the phone, a buyer who's saying, "well, I walked through the house the other day and this is what was wrong. The ceiling was cracked over here." You get it from one to the Realtor then that Realtor conveys it to the other Realtor and then that Realtor conveys it over to the owner and by that time, we went from a crack in the ceiling to the skylight that has fallen into the living room. It's a whole lot easier and as Stuart mentioned, the speed, if I'm that agent, the property that I've gotten, let's face it. I probably have and if I have a shame on me, already have a Matterport model of this property that I'm selling. There's nothing different than it has to be done with it to ingest it inside of NSPECT. It's just give us the link and we'll bring it in. But then that Realtor sends it to their client and the client works on it at night, and then the comments are already there and then the Realtor just sends the report over to the other agent. It's done. There's no more interpolating, there's no more assuming. It's like, "here's the problems that my client has with the property. Go for it, fix it." Take this all the way down to the final inspection of, "we're about to close. I need to deliver, here I want to make sure that these things are done." [00:45:20] Dan Smigrod: I totally get it. As you're talking, I'm visualizing when we purchased the house my wife is living in, are all the issues that were in that multi-page report. "Where was that issue?" There were a lot of people that it had to be communicated to. I'm totally with you on that. Facilities Managers. Take us through the pain points related to facilities management. [00:45:47] Stuart Gilly: Yeah. I think one of the biggest issues is preventative maintenance, and being able to identify what are the things that need to happen proactively that obviously are going to be less expensive and less time or even impact than that's being done in a reactionary standpoint. Also safety. I've lived in that world for a long time and I can tell you there's a lot of things that are safe and they're not. It's not that they seem super intentional as much as it's just somewhat out of compliance type deals that create a big issue. Being able to have people in real time just check on the safety of a facility. Obviously, we talked about this before, the travel cost and time. Typically, the people inside of the facility management are not going to have a ton of resources who are probably your subject matter experts. You're going to probably have a lot of people who are out in the field that are more of the repair-do versus the identify what needs to be done. Again, we still see that or we've experienced that in that industry is one of these limited resources with the skill and knowledge and experience to be able to give better direction. We're seeing that in the facility management side. We think there's obviously a lot of opportunities just in those pain points that we're identifying. [00:47:19] Dan Smigrod: Is there anything more on safety inspections? Maybe in terms of regulatory compliance. [00:47:26] Stuart Gilly: Brandon now that you jump in that since you've got way more experienced in the safety regulatory -- [00:47:32] Brandon Foreman: We can do a whole another show just on the safety side of this. We found that, if you are in safety and you hadn't found NSPECT yet, you're probably a day away from finding it because it's just going rapidly through the industry. You could be on the small side of things, but if you're big, you've got OSHA knocking on your door or you've got different things; you need to know. One of the most important things other than keeping people safe is document and compliance. There's regulation to where yes, you've got to do these things and everybody makes mistakes. But if you can show that, "hey, our fire extinguishers, we check them every single month. You just happened to show up the day after my tag expired. I would have caught that next week and they go, 'well, you do it every month?" 'Yes. Let me show you. Here is last month's report. Here's this month's report, here's this month, January, February, March'" it makes a world of a difference, not to mention gives these safety inspecting -- This is a small community that works really hard, but allows them to communicate with each other, allows them to learn when there is unfortunately an incident. They can go back and they can look and capture that space. "What could we have done better?" But really where we find safety gets involved is, I'm a medium-sized company. I don't have a full HSE [Health and Safety Executive] on staff. I work with a consultant. My consultant can only get to my facility once every 90 days or once every six months or that's all I can afford to fly him out and to go through it. Grab your iPhone, get a Matterport Axis rotator. Scan the facility, send him a link, the NSPECT project and say, "Bill, what I'm I missing?" "What have we done wrong? Do you see anything out of line?" "Yes, you can't leave that ladder leaning there. You're missing the Unistrut bracket over here. You don't have tie offs over here." Those are things that can be done while Bill dropped his kid off at school, as Stuart said, and came back home and sat at the kitchen table or on the couch and was able to mark those things up and we didn't have to wait for him to get on an airplane. We didn't pay for hotels and we got immediate information that we don't have any data, but maybe we're saving lives along the way. [00:49:49] Dan Smigrod: I'm hearing about saving lives and reducing accidents; all the things that are related to safety that we obviously want to hear are saving lives, reducing accidents. Talk a little bit more thought about regulatory compliance and documentation. You gave an example on the fire extinguisher that expired the next day and there was being able to show the history of -- that the fire extinguishers are inspected every month and here's the documentation for it. How important is it to be able to have documentation within a three-dimensional model where there is this annotated history? [00:50:43] Brandon Foreman: First and foremost, I'm not with OSHA. I don't ever want to be and don't pretend to be and I did not stay at a Holiday Inn last night ;-) But with that said, I think what's important with anything is if I go scan a facility, if I'm using just a Matterport model and I scan the facility, if I don't have the documentation to prove that I either knew that I did it correctly or noticed that there was a problem. Just having a simple digital twin of a facility that's got safety violations or has met everything, there's something to be said for, "here's my report from January, February, March, and I can show you every infraction that I found and it was fixed the following month. Here's everything that we did correctly and I've verified that we did it correctly and I've got it documented" versus just saying, "well, we scanned our building once a month and we all looked at it." Well, you looked at it and that's where the birth of NSPECT really came. When you sat in a boardroom and you had that conference, as Stuart alluded to earlier and said, this is great. But I can't take a Matterport model and put it in my pocket or I can't go put it in a file cabinet and if OSHA knocks on the door one way or another regulatory body and says, "show me that you knew that you were taking the right steps." I can say, "look, there's a non-slip surface mat right here" and I pointed it out. You don't point out everything that's wrong. Point out what you did there was right. Point out what you're doing across the board. Show the good things and show the bad things and then show the bad things corrected. That's what you need to be able to do. It's about documentation. [00:52:18] Dan Smigrod: What about reports and analytics? [00:52:23] Brandon Foreman: Well, I'm referring to the report you would print. [00:52:26] Dan Smigrod: Let me ask the question a little bit differently. "I have a company with 147 locations in 36 states and one of the things that we are using Matterport + NSPECT for is related to fire extinguishers." Now that said, fire extinguishers are only one line item of things that are regularly inspected. Can you use NSPECT to generate a report to say, "all my locations, all fire extinguishers and I want to know the status, they're all marked safe or inspected?" [00:53:09] Brandon Foreman: Yeah. You can go in and filter by fire extinguisher. You can pull the data. We've got open access to that data where we dump it either to your system or if you want to pull it from us. But you're able to go in and show "here's when I scanned it, here's when I actually checked it." There's this difference between a scan date and report date, you might have scanned last week versus reported this week. We're going to know that and we're going to be able to show that we're consistent. That's one of the things and I didn't know I was about to bring this up, but I thought you might have been going there, but if I've got 147 locations and we're checking fire extinguishers, well, guess what? I can have the same two guys that know to the letter of how we want our compliance and consistency. "I don't do well, this guy checks here, this guy runs there." It's done by the same people, the same two guys, they print the same report out, they put it in the same folder, it's in the three ring binder, and we're consistent on it. That's what these safety guys want. That's what they wanted to know, that we got 147 locations and we just didn't have time to get to that last one and so we just stamped it and moved on. [00:54:21] Stuart Gilly: Dan, can I add one point to that? [00:54:22] Dan Smigrod: Yes, please. [00:54:23] Stuart Gilly: I think the other thing that's really important about this, and we may have skipped right over this, but imagine there's 147 locations around fire extinguishers and one of the guy's in Seattle and the other guy is in Chicago, who are responsible. They can collaborate inside of NSPECT in real-time, just like they're in the office together. It's not only about being able to push it out to other third-party vendors and contractors and clients and whoever else but it's also the ability that they can work inside the same file, in the same system across offices and be able to in real time have that asynchronous communication with it. I just wanted to make sure we brought that up too. [00:55:06] Dan Smigrod: Awesome. [00:55:06] Brandon Foreman: Here is the last point I'll make with that. This is not to be a jab, but for the guys who are really worried in those executive teams, when you've got your HSE guys, how do you check your HSE guy? You can take this and send it to someone else and say, "here's our report. Here's everything that we found that we're doing good. Here's everything that's bad. Here's the things that we need to work on. Do you see anything that we missed?" And we don't have to fly those guys in, they can review the whole report, they can mark up with their own reported items and say, "we need to do a little bit of training on your guy. He needs to know a little bit more about fall protection because he missed a couple of things." [00:55:50] Dan Smigrod: Before we wrap it up, I just have a couple of last items. First, just to comment on the safety, I'm not a lawyer, I don't give legal advice. But I suspect if you had Matterport + NSPECT, and you had the history documented, you might stay out of getting fined for something where you have demonstrated that you are actually taking action on a consistent basis and annotating it and being able to provide reports on it so that the intent is shown even if something got missed somehow, some way. It just seems like it might save companies from getting a very large fine because of the documentation. I want to move on to just two more topics and I'd like to be brief on them. The first is, I could imagine that there's either some states or some countries that are starting to say, "oh, we actually need to have some type of documentation regarding the safety of buildings." Is that something you want to speak to Brandon? [00:57:04] Brandon Foreman: Yeah. There's some new things that we're seeing that are happening across the pond in the UK. There's obligations, there's the UK Building Safety Act (BSA) that just went into play. That is without getting into the details for anybody that doesn't know, and I think what we see across -- is somebody -- domino's first. Some country says, "we're going to do this" and then everybody else is going, "well wait, if they're going this hard on safety, why aren't we? The UK Building Safety Act is requiring building owners of certain sizes and number capacity of people -- they have to document this. It's not going to be enough to not have a digital twin. You're going to have to have a digital twin, you're going to have to document it out, which it's as I said at the beginning, it's we fell by accident and to be in the reporting engine for Matterport. [00:57:54] Dan Smigrod: Given what's going on in the UK, where does Matterport + NSPECT fit in as a solution? Is this a bulls-eye? Is this spot on? [00:58:06] Brandon Foreman: I wish I could have said I could have predicted it, but put it this way, you've got to make your digital twin. We both need it, and you can spend hours with screenshots and annotation tools and getting inside of Google Docs or Word docs or PowerPoint. Or you can grab a seat at NSPECT and be done very quickly because you can just point the problems out, print your reports, put them in the file and you're done. [00:58:31] Dan Smigrod: I want to go back to something that Stuart said at the very beginning of the show. You started out using Matterport as a solution for a specific problem, but it turned out that really Matterport was a tool, it wasn't the solution. I suspect that some of our viewers have looked at Matterport and have moved forward with creating hundreds, if not thousands of models across the United States or around the globe. I have just come to the same conclusion -- that you all came to and started NSPECT. If I am a big time Matterport -- I'm creating hundreds, perhaps thousands of Matterport digital twins and I am trying to manually do all the things you talked about Stuart at the top of the show, what's my next step? What should I do? [00:59:38] Stuart Gilly: Well, you can go to our website www.NSPEC.net and you can book a demo. We'd be more than happy to walk you through a quick little demo like we saw, but more importantly, we want to learn more about you and your business. How are you leveraging Matterport 3D models? How are you using Matterport to deliver business results? If you were maybe sitting in the boardroom where we were when we started NSPECT, you're probably realizing it's a really great tool and it's great information. But if you're not taking that one or two steps further, you might be missing an opportunity to really deliver some good business results and save yourself time and money on all these things. That's what we would say, go book and demo, come check it out. We'd love to see everybody try to find how Matterport 3D digital twins + NSPECT help you run your business better? [01:00:32] Dan Smigrod: Awesome. Brandon, would you like the final word before we say bye? [01:00:38] Brandon Foreman: No. I'm usually the guy talking a lot so I appreciate Stuart carrying me a little bit here. I think at the end of the day, we've got the ability for people to go get the NSPECT product, play with it, get a demo, see how it works in their world. Dan, when we started this, safety was a really big focus for us. But we've had people call us on a weekly basis that are scheduling demos that are doing things with NSPECT that we had no idea. We talked to somebody the other day and they were doing legacy fulfillment. But it was just because they needed to get information from their customer. It was never even going to be facing, it was just a way to take a Matterport model and get people to explain things and point out where things were kind of like we talked about in that real estate world. We didn't know. We've had insurance companies wanting to basically point out all the expensive items in the home and we want to know exactly what that is and put the serial number on it, take the pictures and run the report and give it back to us. Every day we find another use case and Stuart and I and our team will get into daily huddles and it's one of those, "hey, who's got the most unique use case this week?" [01:01:54] Dan Smigrod: Let me take it from there and suggests that if you are watching today show and you are creating dozens, hundreds, or thousands of Matterport spaces, and you're scratching your head about what else you can do with Matterport regarding recording inspections, communicating actions, or documenting compliance, go to www.NSPECT.net, check out the website, you can book an appointment and have a consultation to say, "this is how we're using Matterport. Here or our problems or challenges our hopes, wishes and desires; NSPECT how can you help us? Brandon, Stuart, Thanks for being on the show today. [01:02:40] Stuart Gilly: Yes. Thank you, Dan. Dan, thank you for what you're doing. I know you're bringing a lot of information around this new technology to people and so we're big fans of the show and watching you and seeing everything you are doing. Thank you for your leadership. [01:02:56] Dan Smigrod: Thank you, Stuart. We've been visiting with Stuart Gilly, Vice President of marketing of NSPECT and NSPECT Founder Brandon Foreman. NSPECT, a Matterport partner located in Baton Rouge, Louisiana. For Brandon and Stuart, I am Dan Smigrod, Founder of the We Get Around Network Network Forum, and you've been watching WGAN-TV Live at 5. |

||

| Post 2 • IP flag post | ||

Pages:

1This topic is archived. Start new topic?